Since 1969, Electric Motors

Within the CME Division, located in Madignano (CR), for over 50 years, we have been designing, winding and assembling electric motors, orienting ourselves with refined specialization towards the production of small customized tubular motors.

We are able to produce small, medium and large motors series based on the customer’s specific design.

The continuous technological progress put in place allows us to guarantee a high quality product and services.

MADE IN ITALY PRODUCTION

Thanks to the investments in new production systems, today we are projecting ourselves towards all world markets with a complete range of customized asynchronous electric motors, in order to meet the different needs of customers.

From the choice of the raw material to the final testing tests, each phase of the production process is aimed at the quality that defines the Made in Italy.

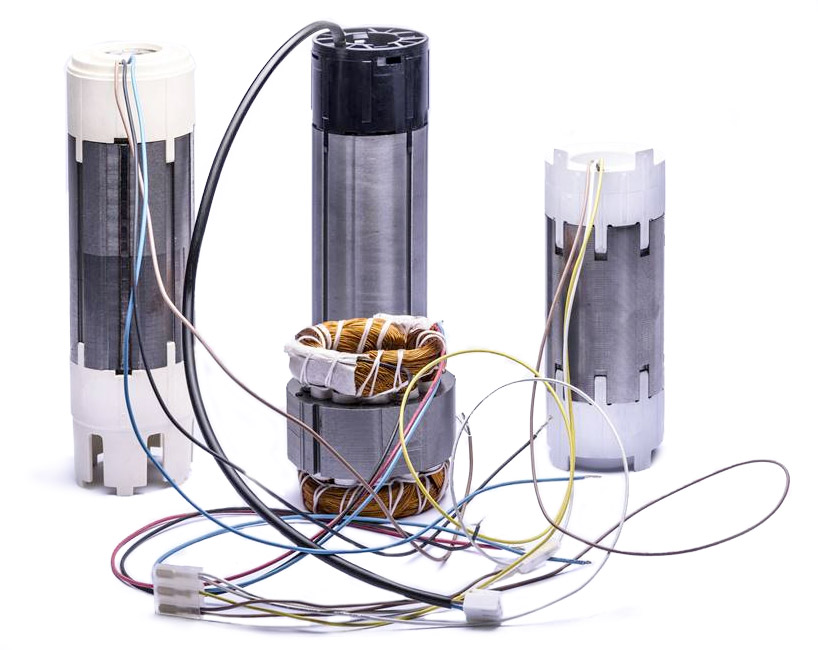

Current types of motors

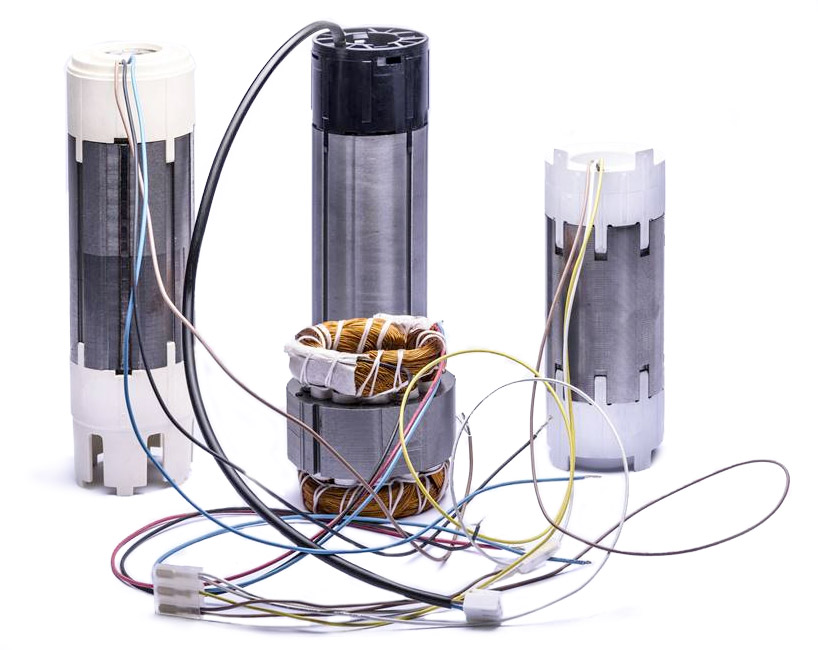

Currently the production of CME is based on the assembly of small / medium asynchronous single-phase and complete electric motors, for aspiration and residential ventilation appliances and for more particular applications, as well as complete three-phase electric motors for sectors related to vibration and similar.

Processing steps

The market for electric motors and motor-reducers is increasingly demanding in terms of product quality, price competitiveness and reduction in design and production times.

Thanks to a dedicated production plant, in CME we offer the best solution for customer needs.

We also work as a partner in the development of new strategic projects, starting from the process / product feasibility up to the final static and dynamic testing in order to minimize the serial production risks.

In this area we insulate raw stator packs through 4 highly efficient machines.

In addition, we have various equipment to

isolate different types of stators, both on the basis of the quarries number, and on the type of insulation used.

Insulation

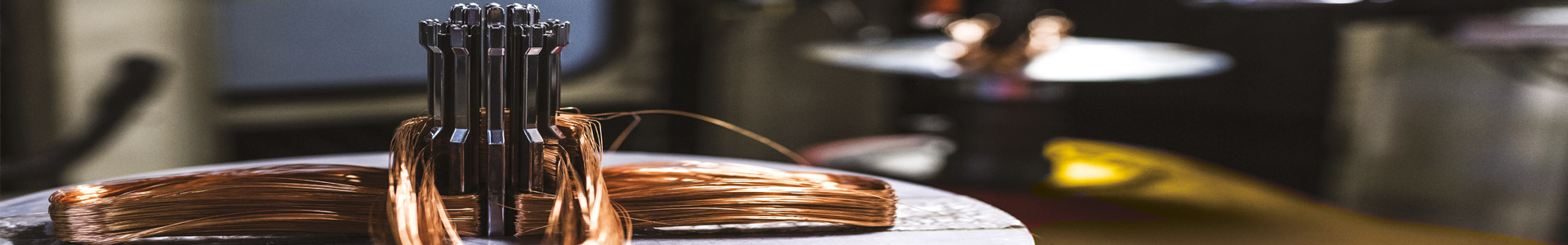

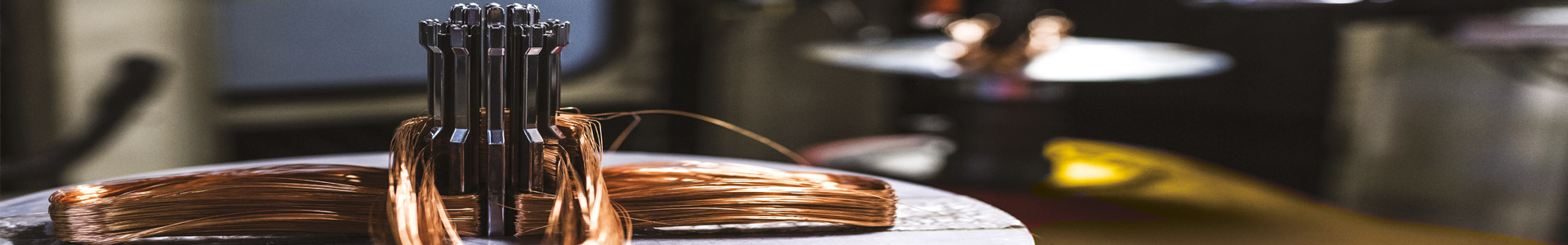

Winding

In this historic area of CME, we have 12 semi-automatic machine groups, prepared for both mass production in series and for sampling new types and new projects.

For the production of large series of electric motors, two latest generation machine groups are reserved

also equipped with automatic loading and unloading lines.

In combination with the insertion and winding,

we carry out the molding of the copper inserted inside the quarries

a fundamental process to allow the staff to finishing and matching the components according to the established tolerances, thanks to 9 presses, both vertical and horizontal.

Molding

In-line finishing

In this department, equipped with automatically managed handling lines,

we work and assemble the wrapped and formed stator pack with the help of specialized employees

who represent the craftsmanship of our motor division.

Thanks to 3 technologically advanced test stations,

we are able to offer 100% quality control of the finished stator

as well as being able to record all the technical specifications, which are also sent to the customer on request, in order to be able to compare our parameters to theirs.

Stator Testing

Matching between Stator and Rotorshaft

This operation makes it possible to supply substantially the complete motor, therefore it requires particular precision.

For this reason, we have specialized employees capable of assembling the rotor shaft supplied by the ALINTECH division.

Inside CME there is an identified area dedicated to the

assembly of all the necessary components to be able to supply complete electric motors and gearmotors

where there are also small machines, such as presses and others.

Assembly

Dynamic testing

Despite the fact that the stator package has already been tested, the motor undergoes the final dynamic test at the end of its processing cycle, which includes the following tests:

measurement of speed and direction of rotation, dielectric strength with measurement of partial discharges and noise test

QUALITY AND DESIGN

With the aim of insuring a product / service conforming to customer needs, we carry out accurate controls throughout the process:

- acceptance check of raw materials and all components;

- online controls during production;

- traceability control;

- final inspection of the finished piece by means of static and dynamic tests.

Furthermore, we actively participate in the development of customer projects, advising them in choosing the ideal raw materials and winding data based on the application of the engine.

In fact, we set ourselves as reliable partners to develop finished products: from insulation characteristics, to technical specifications, from machining of rotors with shaft, to the assembly of gearmotors.

Thanks to the experience gained over the years, we can produce motors in the standard 230V / 50Hz, and 110V – 120V / 60Hz voltage range, or in the “UL” version, using the materials needed to meet the requirements of the various certification bodies.

CME Division

Since 1969, Electric Motors

Within the CME Division, located in Madignano (CR), for over 50 years, we have been designing, winding and assembling electric motors, orienting ourselves with refined specialization towards the production of small customized tubular motors.

We are able to produce small, medium and large motors series based on the customer’s specific design.

The continuous technological progress put in place allows us to guarantee a high quality product and services.

MADE IN ITALY PRODUCTION

MADE IN ITALY PRODUCTION

Thanks to the investments in new production systems, today we are projecting ourselves towards all world markets with a complete range of customized asynchronous electric motors, in order to meet the different needs of customers.

From the choice of the raw material to the final testing tests, each phase of the production process is aimed at the quality that defines the Made in Italy.

Current types of motors

Currently the production of CME is based on the assembly of small / medium asynchronous single-phase and complete electric motors, for aspiration and residential ventilation appliances and for more particular applications, as well as complete three-phase electric motors for sectors related to vibration and similar.

Processing steps

The market for electric motors and motor-reducers is increasingly demanding in terms of product quality, price competitiveness and reduction in design and production times.

Thanks to a dedicated production plant, in CME we offer the best solution for customer needs.

We also work as a partner in the development of new strategic projects, starting from the process / product feasibility up to the final static and dynamic testing in order to minimize the serial production risks.

Insulation

In this area we insulate raw stator packs through 4 highly efficient machines.

In addition, we have various equipment to

isolate different types of stators, both on the basis of the quarries number, and on the type of insulation used.

Winding

In this historic area of CME, we have 12 semi-automatic machine groups, prepared for both mass production in series and for sampling new types and new projects.

For the production of large series of electric motors, two latest generation machine groups are reserved

also equipped with automatic loading and unloading lines.

Molding

In combination with the insertion and winding,

we carry out the molding of the copper inserted inside the quarries

a fundamental process to allow the staff to finishing and matching the components according to the established tolerances, thanks to 9 presses, both vertical and horizontal.

In-line finishing

In this department, equipped with automatically managed handling lines,

we work and assemble the wrapped and formed stator pack with the help of specialized employees

who represent the craftsmanship of our motor division.

Stator Testing

Thanks to 3 technologically advanced test stations,

we are able to offer 100% quality control of the finished stator

as well as being able to record all the technical specifications, which are also sent to the customer on request, in order to be able to compare our parameters to theirs.

Matching between Stator and Rotorshaft

This operation makes it possible to supply substantially the complete motor, therefore it requires particular precision.

For this reason, we have specialized employees capable of assembling the rotor shaft supplied by the ALINTECH division.

Assembly

Inside CME there is an identified area dedicated to the

assembly of all the necessary components to be able to supply complete electric motors and gearmotors

where there are also small machines, such as presses and others.

Dynamic testing

Despite the fact that the stator package has already been tested, the motor undergoes the final dynamic test at the end of its processing cycle, which includes the following tests:

measurement of speed and direction of rotation, dielectric strength with measurement of partial discharges and noise test

QUALITY AND DESIGN

With the aim of insuring a product / service conforming to customer needs, we carry out accurate controls throughout the process:

- acceptance check of raw materials and all components;

- online controls during production;

- traceability control;

- final inspection of the finished piece by means of static and dynamic tests.

Furthermore, we actively participate in the development of customer projects, advising them in choosing the ideal raw materials and winding data based on the application of the engine.

In fact, we set ourselves as reliable partners to develop finished products: from insulation characteristics, to technical specifications, from machining of rotors with shaft, to the assembly of gearmotors.

Thanks to the experience gained over the years, we can produce motors in the standard 230V / 50Hz, and 110V – 120V / 60Hz voltage range, or in the “UL” version, using the materials needed to meet the requirements of the various certification bodies.