ALINTECH Division, located in Pianengo (CR), is highly qualified in the production of precision small metal parts in and particularly specialized in the creation of milled and rolled worm screws. Furthermore, we produce shaped shafts and rotor shafts for electric motors.

ALINTECH Division

We gave a real crackdown to accuracy

For our customers we are able to produce medium and large series of quality mechanical components based on the customer’s specific design. The continuous evolution of the technology we used, allows us to guarantee quality and professionalism, primary values for our company.

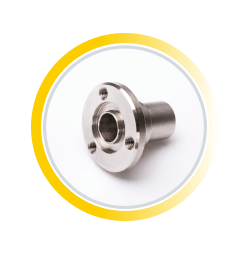

Turning

This department, where all the production is born, represents Alintech’s heart. We are able to produce mechanical components with sliding headstock and fixed head CNC lathing and multi-spindle turning.

For example, we make conical or straight knuckles, blind or through holes, external or internal threads, keyways and tongue.

For example, we make conical or straight knuckles, blind or through holes, external or internal threads, keyways and tongue. Thanks to even more sophisticated numerical control machines, the department has renewed itself in order to satisfy the increasingly numerous requests of customers operating in the field of hydraulic pumps, gearmotors, rack actuators and where molded elements, that require maximum precision, are used.

Machinery

- N° 1 TSUGAMI lathe – Max. Diameter 32 mm.

- N° 1 TSUGAMI lathe – Max. Diameter 20 mm.

- N° 2 STAR lathes – Max. Diameter 32 mm.

- N° 2 STAR lathes – Max. Diameter 20 mm.

- N° 1 STAR lathe – Max. Diameter 16 mm.

- N° 1 CITIZEN lathe – Max. Diameter 20 mm.

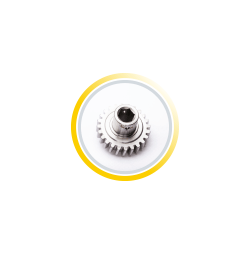

Gear cutting

Inside the gear cutting area we are able to make shafts or wheels with straight and helical gear of maximum module 3, with a maximum diameter of 75mm and maximum length of 120mm, respecting a din class 3974-1 (din8).

We also produce wormgears from 1 to 10 principles, with maximum working diameter of 50mm and length 150mm with roughness Ra1.4 Max for the milled wormgears and Ra0.5 Max for lapped gears. Through automatic deburring, we can deburr the gears even directly in the machine.

Machinery

Gear cutting

Inside the gear cutting area we are able to make shafts or wheels with straight and helical gear of maximum module 3, with a maximum diameter of 75mm and maximum length of 120mm, respecting a din class 3974-1 (din8).

We also produce wormgears from 1 to 10 principles, with maximum working diameter of 50mm and length 150mm with roughness Ra1.4 Max for the milled wormgears and Ra0.5 Max for lapped gears. Through automatic deburring, we can deburr the gears even directly in the machine.

Machinery

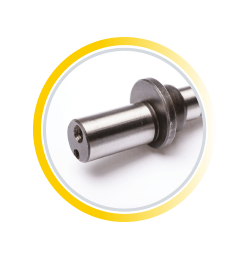

Grinding

In this department 11 grinding machines carry out the finishing of the details, enhancing the complicated processes that occurred in the previous departments. Specifically, we are able to perform external grinding of centerless, single or multi-diameter shafts, grinding on outdoor centers and grinding in the past.

Machinery

Machining of die-casted rotors with shaft

The majority of Alintech’s production is concentrated in this area, equipped with advanced machinery and movement systems for cutting-edge parts. In fact, it represents the technological and development center of the company itself.

Inside we carry out assembly, straightening, turning and grinding of die-cast shafts thanks to the use of fully automated turning and driving islands, inside which it can found various type of anthropomorphic robots.

Machinery

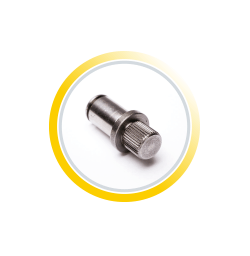

Others processes

In order to maintain high standards, we also carry out finishing processes, such as:

-

millings;

-

external metric, gas, american and whitworth threads;

-

lapping smooth shafts or gearworms;

-

smooth or crossed knurling;

-

chamferings for assembly with rotors.

Finally, each piece, before being packed for shipment, undergoes washing with perchlorethylene in a closed chamber, as well as the application of dedicated anti-oxide protection.

Machinery

-

To realize knurling from pitch 0.5 to pitch 2 straight or crossed by pieces of diameter 6 mm to diameter 25 mm by blade or bush.

-

To make 6 to 25 mm diameter threads.

-

To make laps of smooth diameters or gearworms.